ONLINE INQUIRY

*Note: Please be sure to fill in the information accurately, and keep the communication unblocked, we will get in touch with you as soon as possible

Unlocking Precision: The Essential Guide to Stone Cutting Machines

Time:

Feb 03,2025

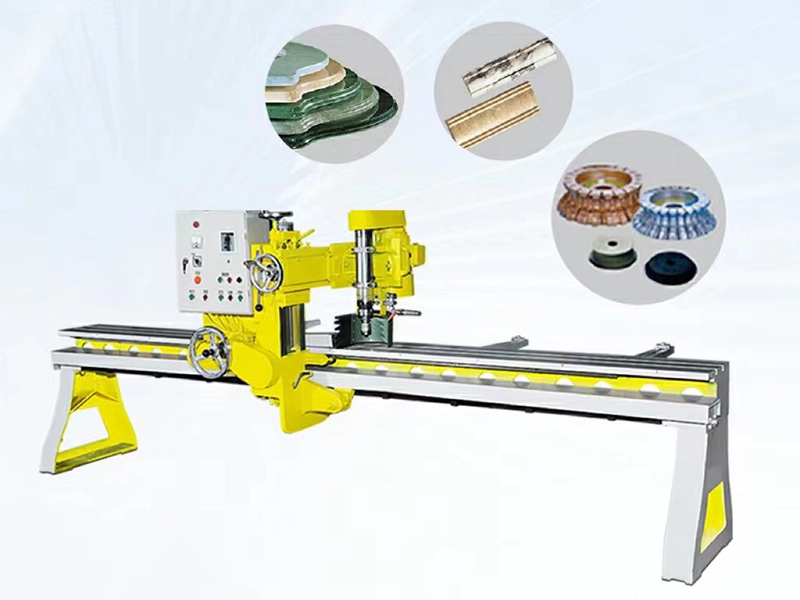

Stone cutting machines play a pivotal role in the manufacturing and processing of stone materials. Designed to deliver precision and efficiency, these machines are essential for various applications, including countertop fabrication, tile cutting, and monument creation. Understanding the nuances of stone cutting machines can significantly impact the quality of work and operational efficiency in the stone industry.

At the heart of a stone cutting machine lies its cutting mechanism, which can vary based on the specific type of machine. The most common cutting methods include diamond blade cutting and water jet cutting. Diamond blades are favored for their durability and ability to cut through hard materials with precision. Meanwhile, water jet cutting utilizes high-pressure water mixed with abrasive materials, allowing for intricate designs without generating excessive heat, which can compromise the integrity of the stone.

When selecting a stone cutting machine, professionals should consider several key factors to ensure optimal performance. First, the machine's power and motor capacity are critical. A more powerful motor enables faster cutting speeds and can handle larger, thicker pieces of stone. Additionally, the machine’s cutting capacity—reflecting the maximum size of the stone it can accommodate—is vital for meeting the demands of various projects.

Another important aspect to consider is the machine’s portability. For many professionals, ease of movement can enhance productivity, especially on job sites with diverse cutting needs. Portable stone cutting machines allow workers to transport equipment easily while still delivering high-quality results.

Safety is another crucial consideration when using stone cutting machines. Operators should always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection. Moreover, ensuring that the machine is equipped with safety features, such as emergency stops and blade guards, can prevent accidents and injuries during operation.

Maintenance is essential for the longevity and efficiency of stone cutting machines. Regularly checking blade conditions, cleaning the work area, and ensuring all components are functioning correctly can reduce downtime and enhance performance. Implementing a routine maintenance schedule can help operators avoid unexpected breakdowns and costly repairs.

In conclusion, stone cutting machines are invaluable tools that significantly influence the quality and efficiency of stonework in the manufacturing and processing sector. By understanding their operation, selecting the appropriate machine for specific tasks, and adhering to safety and maintenance practices, professionals can maximize the benefits of these machines and achieve outstanding results in their projects. As technology advances, staying informed about the latest innovations in stone cutting machinery can further enhance capabilities and open new possibilities in stone processing.

At the heart of a stone cutting machine lies its cutting mechanism, which can vary based on the specific type of machine. The most common cutting methods include diamond blade cutting and water jet cutting. Diamond blades are favored for their durability and ability to cut through hard materials with precision. Meanwhile, water jet cutting utilizes high-pressure water mixed with abrasive materials, allowing for intricate designs without generating excessive heat, which can compromise the integrity of the stone.

When selecting a stone cutting machine, professionals should consider several key factors to ensure optimal performance. First, the machine's power and motor capacity are critical. A more powerful motor enables faster cutting speeds and can handle larger, thicker pieces of stone. Additionally, the machine’s cutting capacity—reflecting the maximum size of the stone it can accommodate—is vital for meeting the demands of various projects.

Another important aspect to consider is the machine’s portability. For many professionals, ease of movement can enhance productivity, especially on job sites with diverse cutting needs. Portable stone cutting machines allow workers to transport equipment easily while still delivering high-quality results.

Safety is another crucial consideration when using stone cutting machines. Operators should always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection. Moreover, ensuring that the machine is equipped with safety features, such as emergency stops and blade guards, can prevent accidents and injuries during operation.

Maintenance is essential for the longevity and efficiency of stone cutting machines. Regularly checking blade conditions, cleaning the work area, and ensuring all components are functioning correctly can reduce downtime and enhance performance. Implementing a routine maintenance schedule can help operators avoid unexpected breakdowns and costly repairs.

In conclusion, stone cutting machines are invaluable tools that significantly influence the quality and efficiency of stonework in the manufacturing and processing sector. By understanding their operation, selecting the appropriate machine for specific tasks, and adhering to safety and maintenance practices, professionals can maximize the benefits of these machines and achieve outstanding results in their projects. As technology advances, staying informed about the latest innovations in stone cutting machinery can further enhance capabilities and open new possibilities in stone processing.

RELATED NEWS